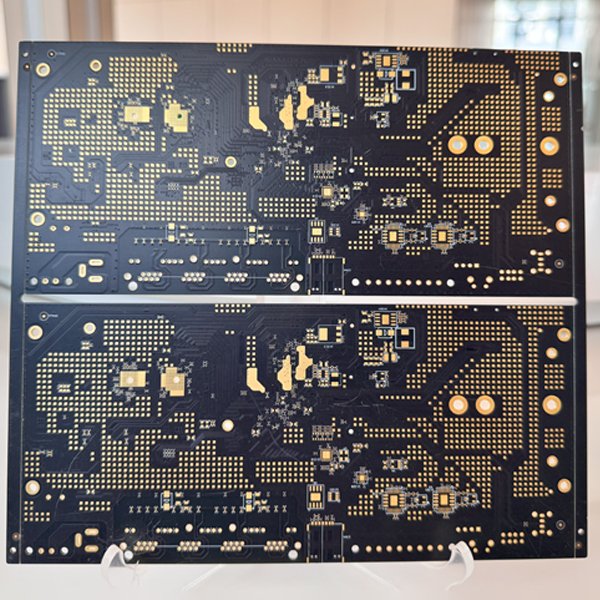

8 Layer Automotive Immersion Gold PCB

8-Layer Automotive Immersion Gold PCB

In the ever-evolving automotive industry, the demand for sophisticated electronics continues to grow, fueling a need for high-performance printed circuit boards (PCBs). Among the advanced options, the 8-layer automotive immersion gold PCB has emerged as a key component in ensuring reliability, durability, and optimal performance across various automotive applications. This article dives into what makes this type of PCB essential for automotive applications and explores its advantages, specifications, and applications.

Technique Capability:

Layer Count | From 2L to 24L |

Material | CEM-3. FR4. High High CTI Halogen Free |

Thickness | Inner: 0.1mm Outer. 0.3-3.5mm |

Copper Thickness & UL | 1/3 OZ, H/H OZ, 1/1 OZ, 2120Z, 3/30Z, 4/40Z, 5/50Z |

Working Panel Size | 760mm x 660mm |

Drill Capability | Blind//buried via, Semi-drill, Finished hole size: 0.15mm -6.5mm; NPTH: ±O.05mm PTH: ±0.075mm Hole Position: ±0.075mm |

Trace width/space | 0.05/0.05mm |

Finishing | OSP. LF HAL, Flash Gold. ENIG. Immersion Tin. (Gold Plating) (Carbon Ink) |

Solder mask | Thickness >= 10um (UV Solder Mask) |

Profile & Tolerance: | Punch, Route, V-CUT; ± 0. 1mm |

Peelable Mask: | Thickness >= 0.3mm |

Warp & Twist: | IPC-A-600G . Max. 0.5% |

Functional Test: | IMPEDENCE, OPEN/SHORT, FLYING PROBE. LOW RESISTANCE TEST; |

Understanding the 8-Layer Automotive Immersion Gold PCB:

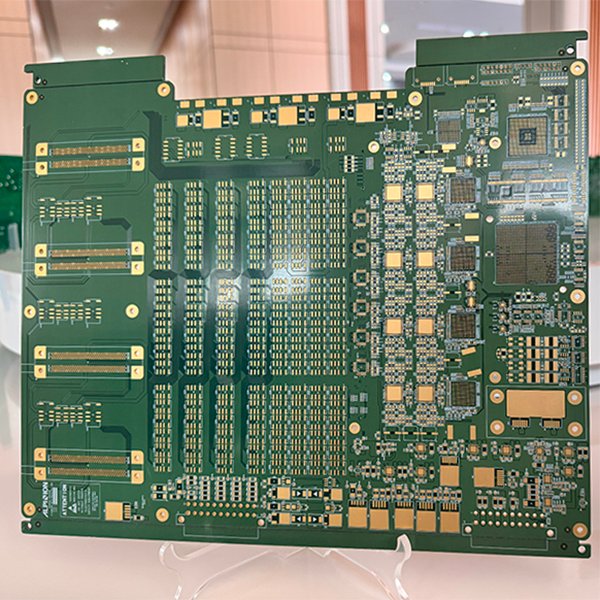

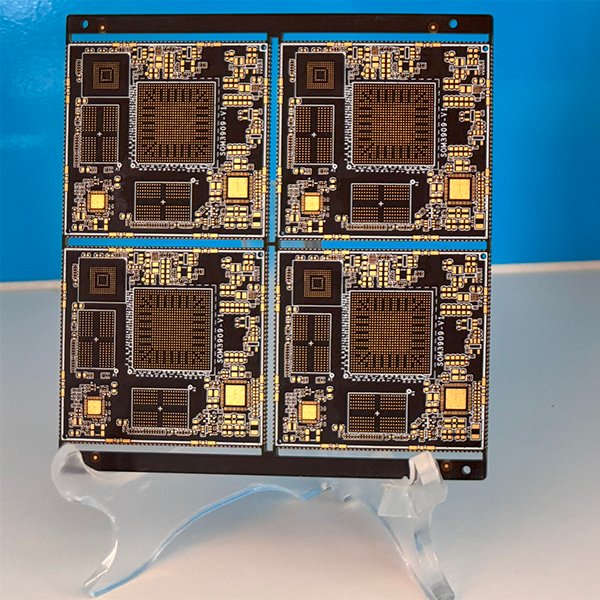

An 8-layer automotive immersion gold PCB is a multilayer printed circuit board consisting of eight distinct layers, each intricately designed to fulfill various electrical and structural functions. The immersion gold (ENIG) surface finish is a significant feature, providing excellent conductivity, a smooth surface, and a long-lasting, corrosion-resistant layer. ENIG involves a double-layer metallic coating—first nickel, then a thin layer of gold deposited over it. This is particularly beneficial in automotive environments where reliability and performance are crucial.

Key Features and Advantages:

1. Enhanced Signal Integrity: The 8-layer design allows for better separation of power and ground planes, which enhances signal integrity and reduces electromagnetic interference (EMI). In automotive applications, where communication and sensor data must be accurate and timely, high signal integrity is vital.

2. Thermal Management: Automotive environments can be challenging due to high temperatures and fluctuations. Multilayer PCBs, especially with an immersion gold finish, excel at dissipating heat and maintaining stable performance in demanding conditions.

3. Durability and Corrosion Resistance: The immersion gold layer provides robust corrosion resistance, essential for vehicles exposed to humidity, road salts, and other environmental factors. The ENIG coating also protects the copper from oxidation, extending the board's lifespan.

4. High Reliability: Automotive electronics must withstand intense vibrations, shocks, and temperature variations. The layered design, in conjunction with high-quality materials like ENIG, makes these PCBs well-suited for such conditions, ensuring reliability over prolonged use.

5. Superior Solderability: The immersion gold finish provides a flat, solder-friendly surface, reducing the risk of defects like uneven solder joints and enhancing the assembly process. This results in a more secure connection, an essential feature for safety-critical automotive components.

Specifications:

An 8-layer automotive immersion gold PCB typically includes the following specifications:

• Layer Count: 8

• Board Thickness: 1.2 to 2.0 mm (can vary depending on the design)

• Base Material: FR4 or high-Tg materials for better heat resistance

• Surface Finish: ENIG (Electroless Nickel Immersion Gold)

• Copper Thickness: 1-oz or more, based on current-carrying requirements

• Min. Hole Size: 0.2 mm or less for micro vias

• Solder Mask: High-temperature-resistant options, often in black or green

• Compliance: IPC standards, RoHS compliance, and automotive-grade certification

Applications in the Automotive Industry:

The 8-layer automotive immersion gold PCB is integral to a range of automotive systems. Some common applications include:

1. Advanced Driver Assistance Systems (ADAS): ADAS requires reliable electronics for processing data from cameras, radar, and sensors. The multilayer design of an 8-layer PCB offers the signal integrity and data-handling capacity needed for this sophisticated technology.

2. In-Vehicle Infotainment Systems: Modern infotainment systems demand high-speed data processing and reliable connections, which an 8-layer PCB can deliver.

3. Powertrain Electronics: Powertrain components, including the engine control unit (ECU) and transmission control module, benefit from multilayer boards' stability and reliability, particularly in high-temperature environments.

4. Electric Vehicle (EV) Battery Management Systems (BMS): In EVs, the battery management system is essential for monitoring battery health and safety. The heat dissipation properties of an 8-layer PCB make it ideal for this high-energy application.

5. Telematics and Connectivity Modules: With the rise of connected cars, telematics modules require highly reliable and durable PCBs to handle continuous data transmission.

Design Considerations for Automotive PCBs:

Creating an 8-layer immersion gold PCB for automotive use requires careful planning and expertise. Key design considerations include:

• Material Selection: FR4 or high-Tg materials are recommended for better temperature stability. The choice of materials directly impacts the PCB’s ability to handle automotive environmental conditions.

• Stack-Up Configuration: Proper layer stacking is essential to minimize EMI and improve signal integrity. Generally, power and ground planes are centrally located, with signal layers surrounding them.

• Thermal Management: Ensuring efficient heat dissipation by incorporating thermal vias or using high-conductivity materials is vital, especially for high-power applications.

• Compliance with Automotive Standards: PCBs must meet industry standards such as ISO 9001, IATF 16949, and IPC-A-600 for quality and reliability assurance.

The 8-layer automotive immersion gold PCB is a robust solution designed to meet the demanding requirements of modern automotive systems. With features like superior thermal management, corrosion resistance, and enhanced signal integrity, this PCB type is indispensable in applications where reliability and performance are non-negotiable. As automotive electronics continue to advance, 8-layer PCBs with ENIG finishes are likely to remain a preferred choice for manufacturers aiming to deliver safety, connectivity, and enhanced vehicle functionality.